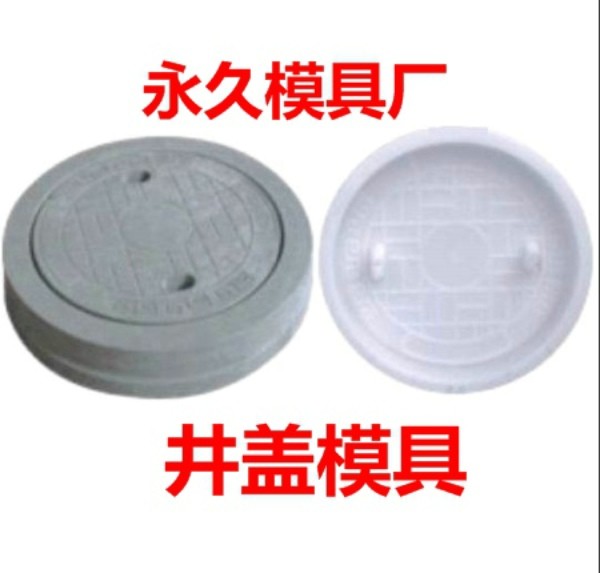

井盖模具是一种很高效的水利工程模具,同时具有节能的特点,修建废物等固体废弃物都能够作为制造模具的材料,一方面节约了生产成本,另一方面还起到了节能的作用。

Well cover mold is a very efficient hydraulic engineering mold, and it has the characteristics of energy saving. Solid waste such as construction waste can be used as the material to make mold. On the one hand, it can save the production cost, on the other hand, it can also play the role of energy saving.

井盖模具主要是采用的钢板焊接而成,因为钢板结构强度比较高,抗压能力强,因为水泥的井盖体积比较大,使用混凝土生产出来的,必须使用钢制的模具

The well cover mould is mainly made of welded steel plate, because the steel plate has high structural strength and strong compression resistance, because the cement well cover has a large volume, and the mould made of steel must be used if it is made of concrete

井盖模具一般都是分为三片或者四片拼装的,组合起来的模具才可以在里面倒入按比例混合好的混凝土,然后使用专门的振动设备,震实出浆,不能有漏震和震动过量产生畸变。

The well cover mold is generally divided into three or four pieces of assembled mold. The combined mold can be poured into the concrete mixed according to the proportion, and then the special vibration equipment is used to vibrate the slurry, without leakage or excessive vibration to produce distortion.

脱模的时候比较简单,把井盖模具拆下来就可以了,然后使用叉车等设备,把井盖挪到存放的地方后期使用。

When demoulding, it is relatively simple, just remove the well cover mold, and then use forklift and other equipment to move the well cover to the storage place for later use.

市场对于井盖模具的要求也就是生产工艺简单,同时水泥制品表面光滑,能够保障按照客户的图纸进行生产,不断地适应于市场的发展

The requirement of the market for the well cover mould is that the production process is simple, and the surface of the cement products is smooth, which can guarantee the production according to the customer's drawings, and constantly adapt to the development of the market