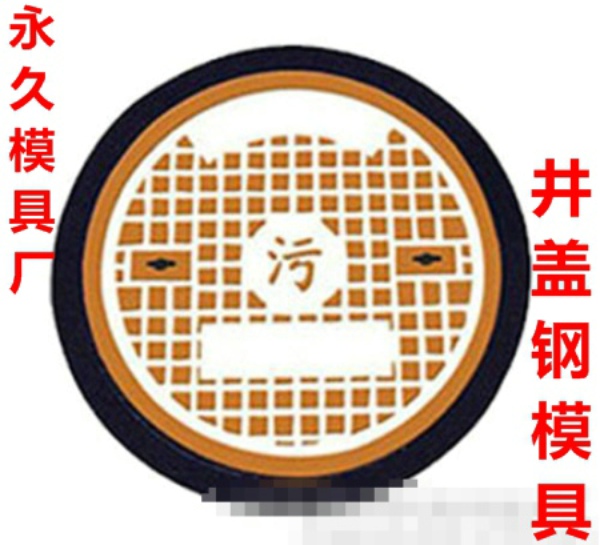

井盖模具生产工艺很重要,模具采用3-5毫米的钢板经裁剪,卷边,焊接,打磨,加固等一系列手工精致而成,使用方便,脱模具快捷,

The production process of well cover mold is very important. The mold is made of 3-5 mm steel plate by cutting, curling, welding, grinding, reinforcing and so on. It is convenient to use and quick to take off the mold,

模具根据设计图纸规定进行生产的,而且成品的模具可以用搅拌好的水泥混凝土,经过设备的振动台震动,让水泥硬化就可以进行脱模,最大优点就是可以循环使用。

The mold is produced according to the design drawing, and the finished product mold can be made of mixed cement concrete, which can be demoulded after the cement hardens after shaking on the shaking table of the equipment. The biggest advantage is that it can be recycled.

井盖模具整个结构包括池体和位于池体上的进污口和出水口,池体内部设有将池体分隔开的隔板,隔板上设有通孔,池体呈圆筒状,其上部设有检查口。

The whole structure of the well cover mold includes the pool body, the sewage inlet and the water outlet on the tank body. The inner part of the pool body is provided with a partition plate which separates the pool body. The partition board is provided with a through hole. The pool body is cylindrical, and the upper part is provided with an inspection port.

相对于普通的池子结构更强,效果更好,出水口处设有防浮板,井盖模具是生产此种产品最重要的设备,提高效率。欢迎需要的来电订购!

Compared with the ordinary pool, the structure is stronger and the effect is better. There is an anti floating plate at the water outlet. The well cover mold is the most important equipment to produce this kind of product, which can improve the efficiency. Welcome to order!