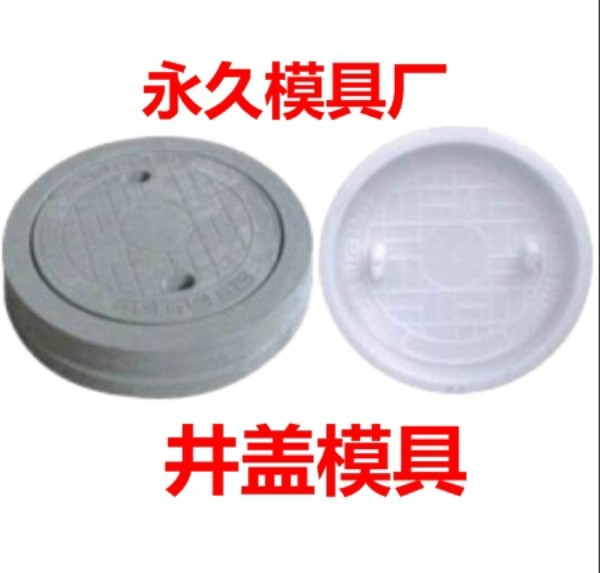

井盖模具主要用于生产水泥防盗井盖使用,井盖模具具的特点是生产出的井盖尺寸标准,适用于小区内,然而模具厂家在制作井盖模具要注意以下几点要求,模具的优先合格的标准就是材质,其次是制作工艺,然后就是实用性,

The well cover mould is mainly used to produce cement anti-theft well cover. The feature of the well cover mould is the size standard of the manhole cover produced, which is suitable for the community. However, the mold manufacturer should pay attention to the following requirements in the production of well cover mold. The first qualified standard of the mold is the material, the second is the manufacturing process, and then the practicability,

由以上三点要求的限制模具基本上都是没有问题的。好的模具在外观和自身的质量上都是显而易见的,模具成型之后不要急于使用,用尺子测量一下看模具的尺寸是不是合格。

According to the above three requirements, the mold is basically no problem. Good mold in the appearance and its own quality are obvious, do not rush to use the mold after molding, use a ruler to measure to see if the mold size is qualified.

跟着模具资料硬度进步,需求模具加工设备具有热稳定性、高可靠性。国内井盖模具井盖模具许稳步向前开展,对井盖模具出产提出更高的需求。

With the development of die material hardness, the mold processing equipment is required to have thermal stability and high reliability. The domestic well cover mold may develop steadily, and puts forward higher demand for the well cover mold production.

以下几条就是提出的要求:提出了高动态精度功能的需求,模具的三维曲面高精度加工.高速高精度还要在机床的高刚性、热稳定性、高可靠性以及高品质的控制系统相配合下才干够完成。

The following are the requirements: put forward the demand of high dynamic precision function, high precision machining of 3D surface of mold. High speed and high precision need to be completed with the combination of high rigidity, thermal stability, high reliability and high quality control system.