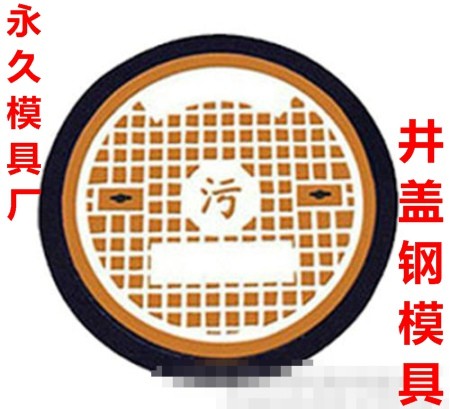

井盖模具注塑设备的进一步发展和制品质量要求的不断提高,都对注塑成型工艺提出了更高的要求,正确选择注塑设备,并合理地设定成型工艺,优化工艺条件,是提高井盖模具质量的关键

The further development of injection moulding equipment for hexagonal slope protection moulds and the continuous improvement of product quality requirements have put forward higher requirements for injection moulding process. The key to improve the quality of hexagonal slope protection moulds is to select injection moulding equipment correctly, set moulding process reasonably and optimize process conditions.

井盖模具的生产首先要保障好模具的产品质量,产品质量的高低直接影响模具的后期使用,模具质量的高低,将直接影响到产品的质量、产量、成本、新产品投产及老产品更新换代的周期.

The production of hexagonal slope protection moulds should first ensure the product quality of the moulds. The quality of the moulds directly affects the later use of the moulds. The quality of the moulds will directly affect the quality, output, cost, production of new products and the renewal cycle of old products.

井盖模具质量好坏会直接影响到生产的成本、生产周期。模具采用的原材料是聚丙烯,这种材料有很好的韧性、可溶性和可塑性

The quality of hexagonal slope protection die will directly affect the production cost and production cycle. The raw material of the die is polypropylene, which has good toughness, solubility and plasticity.

操作步骤简单,同时这种塑料模具可以循环使用,节约能源,侧面起到了环境保护的作用.模具的优势在于性价比高,成本低廉,适合大量生产

The operation procedure is simple. At the same time, the plastic mould can be recycled to save energy and play an environmental protection role on the side. The advantages of the mould are high cost performance, low cost and suitable for mass production.

永久模具的制作技术进一步发展,制作材料也在进行研究,让井盖模具发挥出更好的效果。

The manufacturing technology of permanent mold is further developed, and the manufacturing materials are also being studied, so that the hexagonal slope protection mold can play a better role.