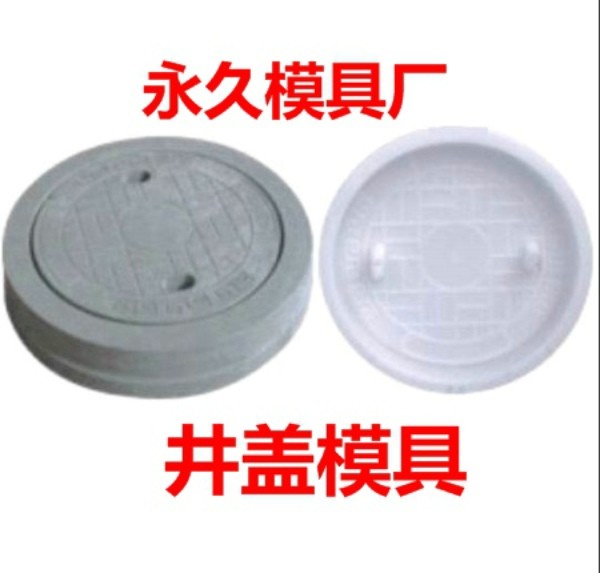

随着工业建设的不断研发与生产,井盖模具的用途越来越广泛,生产制造井盖模具的厂家也越来越多,井盖模具是能够生产出高质量制品的重要模具设备,为工程建设项目开辟了新的道路。

With the continuous development and production of industrial construction, the use of roadside stone moulds is more and more widespread, and more and more manufacturers produce roadside stone moulds. The roadside stone moulds are important moulds and equipment that can produce high-quality products, opening up a new road for engineering construction projects.

模具作为一个重要而特殊的系统,占据着非常重要的地位永久模具厂可以根据用户提供相关模具产品的产品基本信息做出标准件。

As an important and special system, mould occupies a very important position. Permanent mould factory can make standard parts according to the basic product information of relevant mould products provided by users.

生产厂家根据用户所提供的信息配备相关技术人员对模具的结构和工艺性进行分析,设计成模具程序。将原料和配料进行整体的调配,形成一个生产加工过程:

According to the information provided by users, the manufacturer equips relevant technical personnel to analyze the structure and workability of the die, and designs the die program. The raw materials and ingredients are allocated as a whole to form a production and processing process.

首先是对客户所提供的产品信息进行全面的分析和了解。包括井盖模具的原料和配料的选择,模具图纸的设计研究,相关模具的辅助加工准备,相关资料和组织的准备。

Firstly, the product information provided by customers is comprehensively analyzed and understood. Including the choice of raw materials and ingredients for the stone mould along the road, the design and research of the mould drawings, the preparation of the auxiliary processing of the relevant mould, the preparation of relevant information and organization.

然后原材料的调配主要用料聚丙烯,还有各种辅助材料的调配,模具相关配件的锻造加工与连接将测试好的部件进行装配,检测和试模调试。对以加工好的模具进行技术测试,最后对检查合格没有问题的模具打包入库

Then the main material for raw material allocation is polypropylene, as well as the allocation of various auxiliary materials. The forging process and connection of die-related parts will assemble, test and debug the tested parts. Technical testing of processed dies